Three (3) important factors to be considered in evaluating the performance of abrasive used for general cleaning are:

1. How fast cleaning can be completed

2. Uniformity of appearance

3. Cost of achieving desired finish

These factors are determined by the abrasive particle size and shape, the abrasive breakdown characteristics (metallurgy and hardness) and the abrasive-size distribution in the machine. Maintaining an operating mix of the optimal sizes will permit a consistent and cost effective operation. Choose the smallest size shot or grit that will do the job. Choose shot over grit whenever possible to minimize wear. Balance the use of faster

cleaning hard steel abrasives against their higher wear and breakdown rates. |

Tumble Blast Machines

Tumble Blast Machines Swing Table Shot Blasting Machines

Swing Table Shot Blasting Machines Multi Table Shot Blasting Machines

Multi Table Shot Blasting Machines Shot Blasting for Aluminum Casting

Shot Blasting for Aluminum Casting Spinner Hanger Type Shot Blasting Machines

Spinner Hanger Type Shot Blasting Machines Door Hook Type Shot Blasting Machines

Door Hook Type Shot Blasting Machines Continues Monorail Shot Blasting Machines

Continues Monorail Shot Blasting Machines Roller Conveyor Shot Blasting Machines

Roller Conveyor Shot Blasting Machines Pipe Shot Blasting Machines

Pipe Shot Blasting Machines Plate Shot Blasting Machines

Plate Shot Blasting Machines Strip Shot Blast Machines

Strip Shot Blast Machines Stones and Ceramic Blasting Equipments

Stones and Ceramic Blasting Equipments Cylinder Shot Blasting Machines

Cylinder Shot Blasting Machines Coil & Wire Shot Blast Machines

Coil & Wire Shot Blast Machines Bar Shot Blasting Machines

Bar Shot Blasting Machines Wire Rod Shot Blasting Machine

Wire Rod Shot Blasting Machine Billet Shot Blasting Machines

Billet Shot Blasting Machines Wire Mesh Belt Shot Blasting Machines

Wire Mesh Belt Shot Blasting Machines Shot Peening Machines

Shot Peening Machines Roll Etching Machines

Roll Etching Machines Railway Shot Blasting Equipments

Railway Shot Blasting Equipments  Steel Mill Equipments (Special Machines)

Steel Mill Equipments (Special Machines) Blast Rooms/Plants

Blast Rooms/Plants Pressure and Suction Blast Hand Cabinets

Pressure and Suction Blast Hand Cabinets Paver Block Shot Blasting Machine

Paver Block Shot Blasting Machine Sand Blast Pot Machines

Sand Blast Pot Machines Shot Blast Wheels

Shot Blast Wheels Dust Collectors

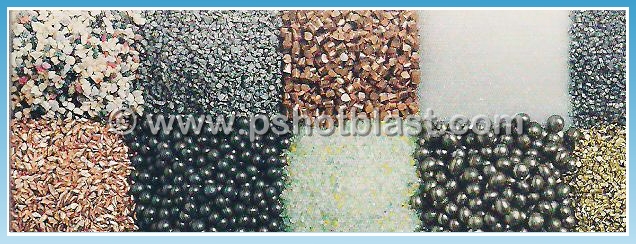

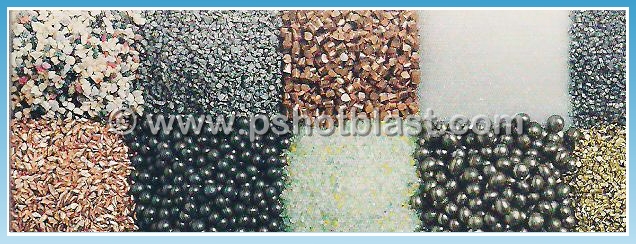

Dust Collectors Abrasives

Abrasives Spare Parts & Accessories

Spare Parts & Accessories ReBar Epoxy Coating

ReBar Epoxy Coating ReBar / TMT Shot Blasting Machine

ReBar / TMT Shot Blasting Machine Aluminum Profile Shot / Sand Blasting Machine

Aluminum Profile Shot / Sand Blasting Machine Scaffolding Cleaning Shot Blasting Machine

Scaffolding Cleaning Shot Blasting Machine