| is taken out manually or on motorized trolley and second loaded hanger is pushed in. Various work handling like Straight, T’s Y can handle 500 Kgs to 1000 Kgs., or more. We have more than 400 machines in operation in India & abroad. Typical components handled are Automobile Components, Textile, Cement, Agro Machinery, Machine Tool Castings, Sanitary Castings, Railways and Defence Components. |

|

| Y Type Hanger Shot Blasting Machine (Fig. 2) |

| Manyauto component contractors use this machine to clean cylinderhead,brake drum, fly wheel and many other components. 500 Kgs., |

|

| Fig – 2 |

| Y hanger will produce 20 to 25 Ton/24 Hours and 1000 Kgs. Y hanger will blast 35 to 40 Ton in 24 Hours (Fig-2)andusing steel shots (abrasive) size 660 (1.70mm) Or S 550 (1.4mm) shots. This includes loading and unloading, blasting. Employing2 to 3 persons giving reasonable return to MSME enterprises and quick delivery for foundry.There are several new features added to our shot blasting machines design to improve quality, increase production and reduce power. Some of the features are as follows : |

|

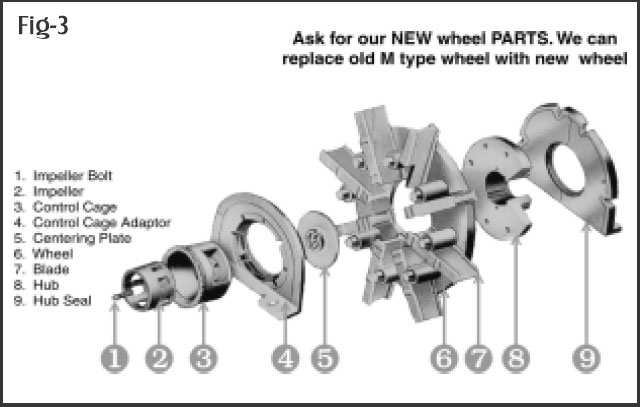

| New RLM Wheel (Fig.3). |

| With need to increase output it has become apparent that shot blasting cycle on the machine must be reduced. In effort to give increased output we have introduced new RLM wheel, which throws more abrasive and consumes less power.In this way one machine is able to do the work formerly done by two machines. The new wheel has larger control cage and impeller making it possible to throw more abrasive resulting in better and faster cleaning and ease of maintenance. |

|

|

|

| Fig – 3 |

|

|

Fig - 4

|

| Direct Drive Wheel: (Fig.4) |

| Our new direct drive wheel uses direct coupled motors, throws more abrasive as it is running at 2800 RPM, useless space compared to RLM wheel, reduces power usage and it is bi directional, so it will run clockwise and anti-clockwise, so only one set of spares is required which reduces maintenance. |

|

|

With frequency convertors, rotational speed are adjusted and different surface and dimension can be treated. Aluminium, window section, thin wall castings can be blast cleaned without deformation.

|

|

Fig - 5 |

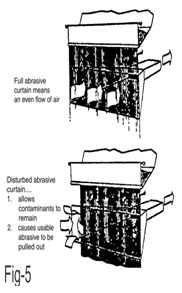

| SEPARATOR Function (Fig.5-6) |

| Foundry sand drastically increases wear on blade, impeller, control cage in blasting machine. Therefore it is necessary to remove sand from shots. The function of the separator is to remove sand and contaminants from abrasive so that good cleaned abrasive of proper size are fed to the wheel. Separator also controls the size of abrasive mix, this gives faster and better cleaning Fig-5 shows setting of the separator which is very important in controlling all phase of operation. What usually goes wrong with separator, |

|

|

|