Fatigue failure of axle Shaft or Spring, Sometime it results in Serious accidents. This Fatigue can be reduced by adoption of Shot Peening Process.  |

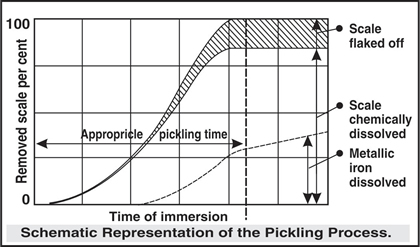

Mechanical shot blasting has many proved advantages over other contemporary process like Pickling Fig. 7 for the following reasons :

(a) The blast surface is ideally suited for subsequent operation.

(b) The finished surface is completely free of scale, dust content and chemical deposit.

(c) A uniform silver matt finish without blemish is obtained.

(d) Shot blasting although removing scale completely, does not remove any virgin metal.

(e) Operation is simple, requiring the minimum of labor and control is by push button.

(f) The machine is entirely suitable for installation in continuous process lines.

(g) The floor area taken up by a shot blast installation is mush less than that normally required for acid pickling. |

(h) There are no attendant problems, such as effluent disposal. (h) There are no attendant problems, such as effluent disposal.

(i) The whole operation is inexpensive and cleaning costs are very much less approx Rs. 480 per ton while pickling which is costing Rs. 3500 / 4000 pre ton for stainless steel strips, wire etc. |

|

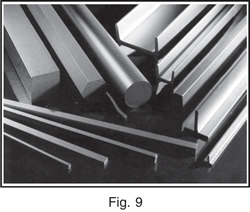

| Shot Blasting is the Cheapest and most effective method for Surface Preparation for steel sections like angles, channels, beams, tee, Pipes & Coils Shot Blasting provides a uniform and consistent fine matt or rough surface. The surface becomes perfectly suitable for painting, galvanizing and powder coating spraying. Shot blasting can form permanent bond between shot blasted surface and protective coating like paint, zinc and epoxy powder coating etc. It also reveals surface defects in the metal. It increases the life of protective coating adheres tenaciously |

|

|

to the scale-free, blast cleaned surface. Thus maintenance cost for repainting can be considerably reduced.

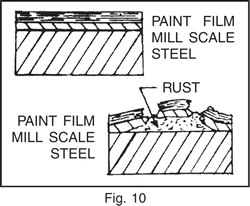

Shot blasting is essential for longer paint life. Various experiments have proved that the length of paint life depends mainly on the strength of bond between  the paint and the basic surface. The quality of this bond depends on the complete and through removal of mill scale, rust and other contaminants prior to painting and on obtaining an uniformly etched surface. the paint and the basic surface. The quality of this bond depends on the complete and through removal of mill scale, rust and other contaminants prior to painting and on obtaining an uniformly etched surface. |

| When paint is applied to sealing, rusty and contaminated steel surface life of paint is poor. |

There will be uneven expansion resulting in cracks in the scale and other contaminants. Those cracks extend to the paint film and to the base metal. Slowly patches of these scale loosen themselves from the base metal and fall off taking the paint film along with them. While doing so, they expose the base metal, rust and the scale to the direct action of the atmosphere or the process conditions. Thus the damage is self multiplying, resulting in total plant failure and even reduction in size of the steel member. Therefore, it is evident that the steel structural should be thoroughly clean of all foreign matters right to the virgin metal. loosen themselves from the base metal and fall off taking the paint film along with them. While doing so, they expose the base metal, rust and the scale to the direct action of the atmosphere or the process conditions. Thus the damage is self multiplying, resulting in total plant failure and even reduction in size of the steel member. Therefore, it is evident that the steel structural should be thoroughly clean of all foreign matters right to the virgin metal. |

| Today shot blasting is the cheapest and most effective method of surface preparation. PF&FPL has supplied shot blasting machines for surface preparation of stainless steel plates, wire rods, angles, channels, flats, round bars, machines having 6 to 16 throwing wheels capable to shot blasting rail couch, wagon ect. Shot blasting is no more an optional process in steel industry. It provides faster and better cleaning. It saves power, labour, space and also saves on cutting tools and permits better inspection, thus minimizing the rejection of castings & steel structural ect. Apart from foundry it is widely used in many other industries. Proper understanding about the machine, its construction and use enables us to improve its efficiency and utility. Before Selecting the equipment it is necessary, to consider vender capacity, spare parts, availability, sales services offered, and many other points. |

|