|

Shot Blasting in Steel Industry (1/2) Shot Blasting in Steel Industry (1/2) |

| |

SHOT BLASTING IN STEEL INDUSTRIES

By. Mr. P. A. PATEL

PATEL FURNACE & FORGING PVT. LTD.

A - 2/510, G.I.D.C., Makarpura, VADODARA - 390 010.

E-mail : info@pshotblast.com / sales@pshotblast.com website : www.pshotblast.com M. : +91 9737061333 |

|

|

|

The purpose of this article is to make the users more aware about the shot blasting equipment as well as its design, construction and maintenance. Effective maintenance will improve the finish of components shot blasted. It will also reduce operating cost, which is approximately 18 to 20 paise/kg depending upon power, abrasives, spare parts and labour cost in different states. |

|

|

|

| Mechanical Shot Blasting |

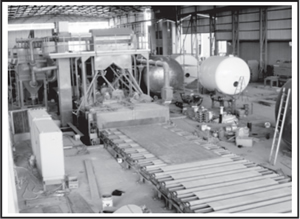

It is widely used in steel industry mainly for de-scaling billets, wires, plates, sheets prior to cold rolling, galvanizing, scale removing and many surface preparation applications. Shot blasting is also used on low carbon, nickel, chrome, silicon steels, titanium and nimonic steel.  The generally accepted machine for this operation is the roller conveyor, Fig. 1 wherein the work is loaded on to an entry conveyor passing through the blast stream within the cabinet to be discharged on an exit conveyor. reclaiming system and must stay within the Amperage capacity of Electric Motor. Shown air operated Soundabrator which reduces noise level, which is below 85 dB and prevents leaking of shots and it is easy to maintain. The generally accepted machine for this operation is the roller conveyor, Fig. 1 wherein the work is loaded on to an entry conveyor passing through the blast stream within the cabinet to be discharged on an exit conveyor. reclaiming system and must stay within the Amperage capacity of Electric Motor. Shown air operated Soundabrator which reduces noise level, which is below 85 dB and prevents leaking of shots and it is easy to maintain.

In addition to the de-scaling process, a number of firms use shot blasting as a means of detecting faults on the surface of rolled products. |

|

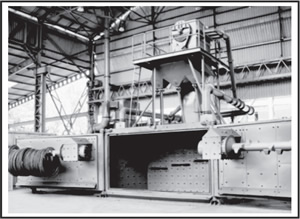

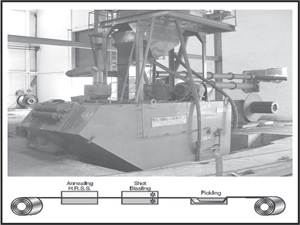

The shot blasting process is also extensively used for the de-scaling of drawn materials such as wire coil, bars, sheet etc. Fig. 2 Shot Blasting of Stainless Steel Strip : The most lucrative field for the development of shot blasting to be found in the de-scaling of continuous process steel strip. Carbon steel, stainless steel strip ranging from 350mm to 1800mm width are shot blasted at speed of 2 to 15 meter / minute. Patel Furnace Forging Pvt Ltd, has supplied machines for simila application, which are working satisfactorily since lest several years. Fig. 3 The shot blasting process is also extensively used for the de-scaling of drawn materials such as wire coil, bars, sheet etc. Fig. 2 Shot Blasting of Stainless Steel Strip : The most lucrative field for the development of shot blasting to be found in the de-scaling of continuous process steel strip. Carbon steel, stainless steel strip ranging from 350mm to 1800mm width are shot blasted at speed of 2 to 15 meter / minute. Patel Furnace Forging Pvt Ltd, has supplied machines for simila application, which are working satisfactorily since lest several years. Fig. 3 |

|

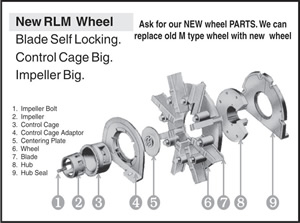

Now let us study in details five basic parts of shot blasting machine : Fig.4 The new wheel (Abrasive Throwing Device); Abrasive fed through opening into Impeller (2), Now let us study in details five basic parts of shot blasting machine : Fig.4 The new wheel (Abrasive Throwing Device); Abrasive fed through opening into Impeller (2), |

|

|

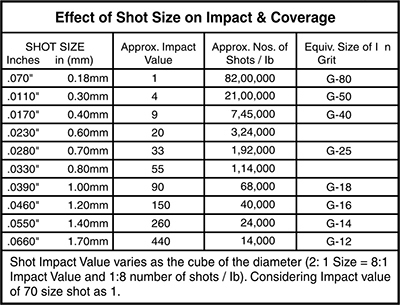

passed through stationary control cage (3), and are immediately picked up by the rotary blade (7), Blade repeats these operations approximately 300 times in a  second. The impact coverage of the steel abrasive is governed by its mass and velocity in accordance with the equation of kinetic energy KE=1/2 MV2, where KE Kinetic Energy, M=Mass and V = Velocity. second. The impact coverage of the steel abrasive is governed by its mass and velocity in accordance with the equation of kinetic energy KE=1/2 MV2, where KE Kinetic Energy, M=Mass and V = Velocity. |

|

|

| Fig 5 |

| wheel diameter and rotation RPM govern the velocity in centrifugal blast unit. Standard 19 1/2" diameter wheel at 2250RPM develops abrasive velocity of approximately 245 ft/ second (or 167 miles per hour). Thus the impact force delivered to the work piece will change only if the mass factor (i.e. the abrasive size) is altered. Fig. 5, which will control surface finish, and roughness. |

|

| Shot Peening : Fig. 6 |

| Shot Shot peening is one of the application for increasing the fatigue life of various components like Coil Springs, Leaf Springs, Gears, Rack & Pinion, Torsion Bar, Connecting Rod, Crank Shaft widely used in auto industries. We See Many trucks broken down on the Road due to |

|

|

|

|

|