| media is shown in (Fig. 13-B) This media is uniform in size and round in shape with no foreign particles or debris. Broken or sharp edge particles can be potentially damaging to the part surface. |

|

| INTENSITY CONTROL |

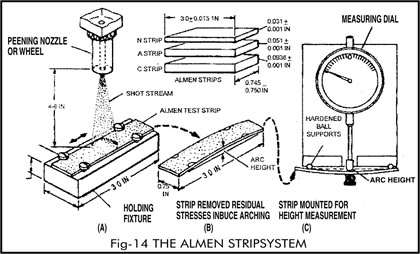

Calibration of the impact energy or peening intensity of the shot stream is essential to controlled shot peening. The energy of the shot stream is a function of the media size, material, hardness, velocity and impingement angle. In order to specify, measure and calibrate peening impact energy, J. O. Almen of General Motors. Research Laboratories developed a method utilizing SAE 1070 spring steel specimens which he called Almen Strips. In his method, an un peened Alemn Strip is fastened to a steel block and exposed t a stream of peening shot for a given period of time. Upon removal from the block, the residual compressive stress and surface plastic deformation produced by the peening impacts will have caused the Almen

strip to curve, convex on the peened surface. The height of the curvature when measured in a standard Almen gauge is called arc height. (Fig. 14) illustrates the concept of the Almen system. An almen strip shall not be reused after peening.

TherFig-14 THE ALMEN STRIPSYSTEMe are three standard Almen strips currently in use “A” strip 0.051 inch thick, “C” strip 0.094 inch thick and “N” strip 0.031 inch thick. The approximate relationship between the A, N and C strips is 3N=A=0.3C. The usable range of curvature on the Almen strips is 0.004 to 0.024 inch. Intensity designations should include both the arc height and the type of Almen strip used. e.g. 10A intensity 0 0.010 inch (0.25mm) arc |

|

|

| SATURATION |

|

|

|

|

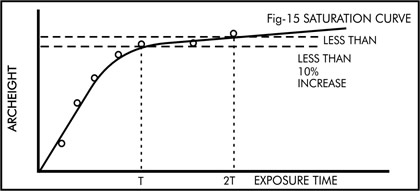

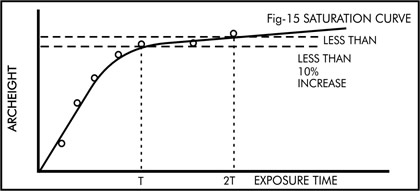

unless saturation is achieved. In order to measure Almen strip saturation, an intensity curve must be developed. When a series of Almen strips are peened with a fixed machine setting for different exposure times, a saturation curve similar to the curve shown in (Fig. 15) can be developed. Saturation is defined as the earliest point on the curve where doubling the exposure time produces no more than a ten percent (10%) increase in arc height.

It should be understood that saturation of the Almen strip and coverage to the part are not the same, nor will they necessarily occur at the same exposure time on the parts being peened. Saturation is the calibration of the energy of the shot stream. Coverage refers to the population of peening dimples on a surface as verified by coverage inspection techniques. Saturation time is determined on an Almen strip of hardness HRC 44-50. If the part being peened is much softer than the Almen strip, it will cover in a shorter period of time. Conversely, if the part being peened is much harder than the Almen strip, it will require a correspondingly longer exposure time to the shot stream, because the dimples on the harder surface will be smaller.

The saturation curve established the actual intensity for the particular machine setup, measured at the location onn the part as indicated on the drawing. In order to establish and maintain proper control and reliability shot peening must be performed in controlled peening machinery where the Almen strip/s and the parts will be exposed to the same conditions required by previously established and approved procedures. |

|

| Concluding Remarks : |

shot peening in no move and optional process in Auto industries for uniform results the job should be passed through shot peening machines, which is well controlled one should insured that all surface subjced to high repetitive stress are uniformly covered by the wheel blast, for low volume of production air blast might be sufficient, how ever for high rate of production the airless wheel type method involving rotating blades wheel is more productive and economical Fig .16 A.B.C.D.E.F. shows peening machine for (A) Leaf spring (B) Bevel gear (C) Hub (D) Tramission gears (E) coil Spring (F) Torsion rod Before Selecting the equipment it is necessary, to Consider Designing Experiences of Manufacture Spare parts Availability, sales service offered and many other point. with humble begning in 1990 in 20 years we have supplied more than 2500 through shot peening machines, which is well controlled one should insured that all surface subjced to high repetitive stress are uniformly covered by the wheel blast, for low volume of production air blast might be sufficient, how ever for high rate of production the airless wheel type method involving rotating blades wheel is more productive and economical Fig .16 A.B.C.D.E.F. shows peening machine for (A) Leaf spring (B) Bevel gear (C) Hub (D) Tramission gears (E) coil Spring (F) Torsion rod Before Selecting the equipment it is necessary, to Consider Designing Experiences of Manufacture Spare parts Availability, sales service offered and many other point. with humble begning in 1990 in 20 years we have supplied more than 2500 |

|

|