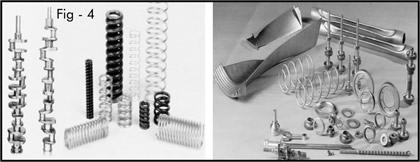

Shot peening increases fatigue life of auto components like Coils Springs, Leaf Springs, Gears, Rocker Arm, Pinion, Torsion Bar, Connecting Rod, Crankshaft and other components for two wheeler and four wheeler and other industries.

It is rear that we go from one place to another by road and not find a vehicle broke down on the road, due to fatigue failure of axle shaft or the spring and so on, thus creating obstacles in the flow of traffic and sometimes resulting in serious accidents. These fatigue failures can be reduced and are being almost eliminated by use of shot peening.

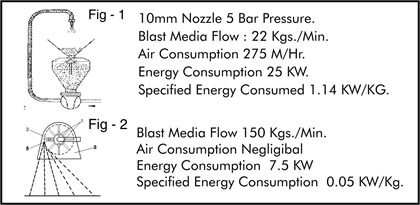

Shot peening is done through shot peening machines. Two Systems of Blasting : Fig - 1 “Pressure Blast System”:In pressure blasting system the blast media is stored in pressurized vessel, which is mixed with compressed air. The air flow accelerates the media, through a blast gun on to the surface. In 'blast Wheel Blasting System : Fig - 2 In blast wheel system the blast media is fed to the center of the blast wheel, which is rotating at high speed. The media is rapidly accelerated by centrifugal force and is directed on the surface to be shot peened. as shown in (Fig. 2.)

This comparison of different blasting systems, clearly shows that the blast wheel blasting system (fig-2) has the lowest specified energy consumption. Blast wheels are driven by electric motors, whereas the air required by the air blasting system (fig-1) has to be generated by a compressor which is to be purchased and maintained in addition to blast machine itself and the additional power cost. |

|

| SHOT PEENING PROCESS |

| Shot peening is a cold working process in which the surface of a part is bombarded with small spherical media |

|

|

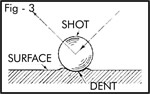

called steel shot. Each piece of shot striking the material acts as a tiny peening hammer, imparting to the surface a small indentation or dimple (Fig. 3). In order for the dimple to be created, the surface fibers of the material must be yielded in tension. Below the surface, the fibers try to restore the surface to its original shape, thereby producing below the dimple, a hemisphere of cold-worked material highly stressed in compression. Overlapping dimples develop a even layer of metal in residual compressive stress. It is well known that cracks will not initiate or propagate in compressively stressed zone. Since nearly all fatigue and stress corrosion failures originate at the surface of a part, compressive stresses induced by shot peening provide considerable increases in part life. for the dimple to be created, the surface fibers of the material must be yielded in tension. Below the surface, the fibers try to restore the surface to its original shape, thereby producing below the dimple, a hemisphere of cold-worked material highly stressed in compression. Overlapping dimples develop a even layer of metal in residual compressive stress. It is well known that cracks will not initiate or propagate in compressively stressed zone. Since nearly all fatigue and stress corrosion failures originate at the surface of a part, compressive stresses induced by shot peening provide considerable increases in part life. |

| A few examples of the type of parts which have shown a good response to shot peening include |

| Crankshafts .................. |

900% |

Life |

Increase |

| Leaf Springs ................. |

600 % |

" |

" |

| Connecting Rod .......... |

1000% |

" |

" |

| Coil Springs ................ |

1370% |

" |

" |

| Gears ......................... |

1500% |

" |

" |

| Steering Knuckles .......... |

475% |

" |

" |

| Rocker Arms ............... |

1400% |

" |

" |

|

| The advantages to be derived from these fatigue life improvements are manifold and affect practically every phase os manufacturing design, production and sales. |

| APPLICATION OF SHOT PEENING |

In general, shot peening will lengthen the fatigue life of any part that is subject to bending or twisting stress. all Two wheels motor bikes like Honda, Bajaj, Suzuki, T.V.S etc. and 4 wheelers Cars like Maruti,  Hundai, Tata Fiat, M & M, B.M.W, Volvo & others uses shot peening process on their components to increase fatigue life of Parts like. Hundai, Tata Fiat, M & M, B.M.W, Volvo & others uses shot peening process on their components to increase fatigue life of Parts like. |

|

|