| FUNCTION AND ROLE OF BLADE , IMPELLER CONTROL CAGE: (Fig.12) |

|

|

The blade plays a key role in shot blasting operation. The blade catch the shot delivered from impeller and control cage and throw out to work pieces with an accelerated speed.

|

|

| Fig – 12 |

|

|

The blade is the quickest wearing part among all moving parts. As the wear widens the disperse angle of shot will change and reduce the projection speed. The blade should be changed every 300 to 400 hours of blasting operation.

|

|

| SHOT & ABRASIVE : (Fig.13) |

|

|

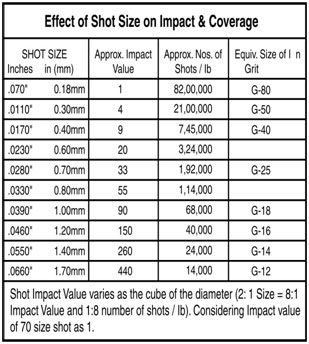

The impact Power, and coverage of steel abrasive is governed by its mass and velocity in accordance with equation of kinetic energy.

|

|

| Fig – 13 |

|

|

Ke = ½ MV2 (Where Ke = Kinetic Energy M=Mass V=Velocity). The impact force delivered to the work piece will change only if the mass factor (i.e. the abrasive size) is altered. The relationship of abrasive size to both impact powerand coverageis shown in figure 13.

The economy and performance of blast cleaning depends upon the abrasives used. The proper size, typeof abrasive and it’s quality are most important. The following five factors should be considered while selecting the abrasives (a) Area of job surface to be cleaned (b) Quality of work produced (c) Cost of the shots (d) Quality of shot. (e) Production in 8 HRS.(f) Consumption of shots in 8 Hours.

|

|

|

| Deburring Aluminum Castings :(Fig.14) |

|

|

Aluminum Die casted components manufactured from Aluminum, Zink & Magnesium Alloys Like Crank Case, Clutch Cover Case, Cylinder Blocks, Brake drum etc.

|

|

| Fig – 14 |

|

|

require to be blasted for removing burrs, and also gives aesthetic value with aim to obtain even, shine finish on all sides. Many users prefer stainless steel shot as the consumption is one sixth of steel shot, carbon steel shot give dull grey finish, while stainless steel imparts matt silver finish pleasing to eye. Many auto units like Honda, Bajaj, Endurance use stainless steel shots.

|

|

| Concluding Remark : |

|

|

Shot Blasting & Fettling are important process in foundry. It provides fast and better cleaning. It saves power. If foundry provides space and finances, small 500 Kgs, Y hanger to MSME enterprises with help of 2 to 3 labours can shot blast and fettle 20 to 25 Ton in 24 Hours and 35 to 40 tons / 24 hours in 1000 Kgs., Y hanger type machine, giving value addition to foundry and employment to new entrepreneurs under “Made In India” scheme. Ours is 100% indigenous machine developed over a period of 30 years’ experience and sold more than 3500 machines in India and abroad.

|

|