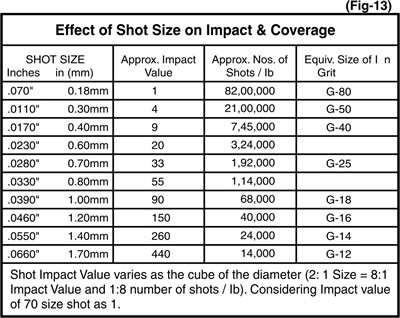

the work piece will change only if the mass factor (i.e. the abrasive size) is altered. The relationship of abrasive size to both impact power and coverage is shown in figure

The economy and performance of blast cleaning depends upon the abrasives used. The proper size and type of abrasives and its quality which is most important. |

|

|

| Shot & Abrasive : (FIG - 13) |

|

|

| Shot & Abrasive : |

| The following four factors should be considered while selecting the abrasives

(a) Area of job surface these can clean

(b) Quality of work produced

(c) Cost of the shots

(d) Quality of shot. |

|

|

|

| Child Iron Shots : |

| The shots are manufactured by quenching the stream of molten gray iron over high pressure water jet. Its hardness is about 60 Rockwell C.Due to this hardness and quenched structure it fractures and disintegrates very quickly on impact with the work surface. Due to greater amount of dust produced in fracturing process, the part cleaned by chilled iron shot does not have very good finish. Also the maintenance cost is very high. This led to the introduction of malleable iron-, cast steel-, cut wire-shots and heat treated steel shots. |

|

|

| Heat-Treated Steel Shots: |

| The heat treated steel shots are having hardness of 45 Rockwell C (424 Brinell hardness). These are the most suitable for the shot blasting machine. |

|

|

| COMPARISON b/w BLASTED & unBLASTED COMPONENTS (FIG -14) : |

|

|

|

|

|

|

| Concluding Remarks : |

Shot blasting is no more an optional process in a foundry. It provides faster and better cleaning. It saves power, labour, space and also saves on cutting tools and permits better inspection, thus minimizing the rejection of castings. Apart from foundry it is also widely used in many other industries. Proper understanding about the machine, its construction and use enables us to improve its efficiency and utility. Before Selecting the equipment it is necessary, to consider above points, spare parts, availability, sales services offered, and many other points, with humble beginning in 1990-in 22 years we have supplied more than 3000 machines for various applications.

Foundry Industry will have to upgrade produce good quality casting and finishing. No buyer will tolerate delay in delivery, defective casting. Foundry will have to adpot new and efficient fettling and finishing practice with several new auto units coming up demand for automotive castings will increase and local manufacturer will have to increase their capacity to meet delivery in time, |

|

|

|

| PANGBORN Our Business Partner : (Fig - 15) |

| We represent Pangborn group of companies which provide solution for surface preparation. The company is located in Europe and USA and have distribution network all over the World the company is technology leader, we proved special machine for auto Industries, aviation Industries, Railway & many other application. |

|

|

|

|